Life Cycle Assessment of Asphalt Using Crumb Rubber Pavement

Life Cycle Assessment of Asphalt Using Crumb Rubber Pavement

Production of a crumb rubber pavement comprises a series of activities, such as materials production, construction, maintenance etc., all of which have environmental impacts. Life Cycle Assessment (LCA) can track and quantify the environmental impacts of both individual and total activities of products. It helps identify the activities with the highest environmental burdens within the life cycle of the product, or point to 2 hotspots and clarify the most environmentally effective strategies among various options. Such advantages make LCA a methodology frequently used to assess the environmental impacts of asphalt pavements. The increasing number of vehicles leads to increasing amounts of tires disposed.

Current solutions to disposing waste tires include the energy recovery (use tires as alternative fuels in cement kilns), chemical recovery (pyrolysis/thermolysis) and granulate recovery (shredding) [1]. Rubberized asphalt pavement is an increasingly popular method that uses the crumb rubber (CR) from waste tires. CR can be either added by wet process or dry process into asphalt mixtures. Although CR asphalt pavements have received positive feedback in other countries [2], their potential ecological benefits/losses are still not clarified. Therefore, in this paper we use LCA to assess the environmental performance of CR modified asphalt pavements. LCA allows to investigate the environmental strengths and weaknesses of using CR.

Asphalt mixtures

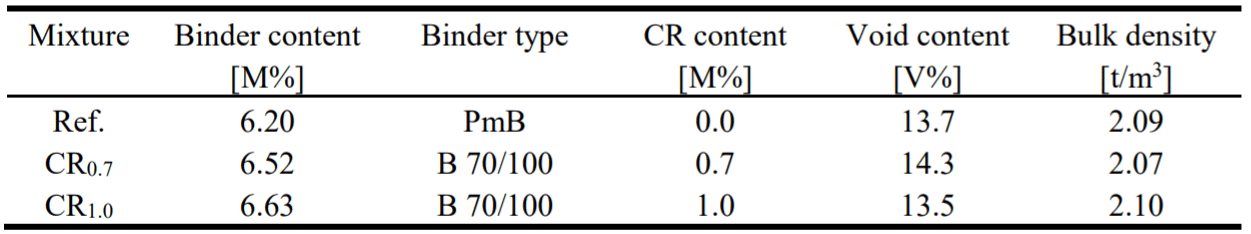

Three types of asphalt mixtures for the wearing courses are prepared in plant. The mix designs are SNR 640436 for SDA 4-12 (maximum particle size: 4 mm, air voids content: 10-14%) [3], and their details are shown in Table 1.

Table 1. Information of reference and test asphalt mixtures ([M%]: by weight of total mixture, [V%]: by volume of total mixture, PmB: polymer modified binder)

To compare the mechanical performance of investigated asphalt mixtures, the cooperated study conducted the water sensitivity test (EN 12697-12) and wheel tracking test (EN 12697-22) [4]. The results showed that the indirect tensile strength ratios of all the specimens are comparable, ranging from 76 to 81%; the rutting ratio of Ref. and CR1.0 are both 6.0% at 30 000 cycles, while CR0.7 has less rutting ratio of 4.4% [4]. Based on the available test results, this initial study assumes that the CR wearing courses have the same service life as that of the reference. In the future study, further tests need to be employed to estimate more accurate service life.

Life Cycle Assessment of Crumb Rubber Pavement

The international standard ISO 14040 divides LCA into four steps: goal and scope definition, inventory analysis, impact assessment and interpretation [5]. For the case of wearing courses, all the four steps are explained as follows:

Goal and Scope Definition of Crumb Rubber Pavement

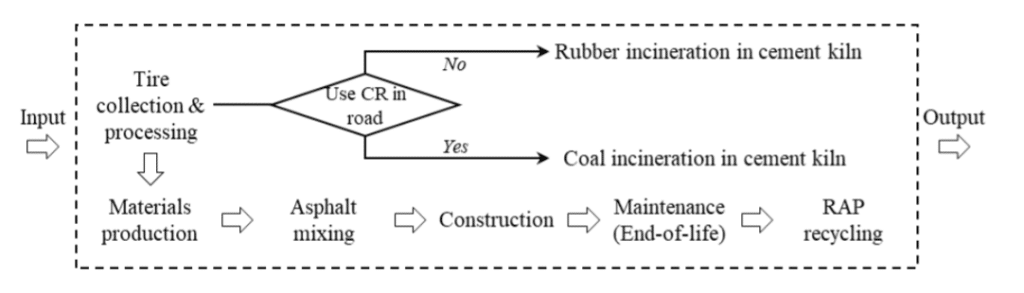

LCA is used to quantify and compare the environmental impacts of reference and CR wearing courses. The functional unit (FU) is constituted by the wearing course with the dimensions of 1 km length, 7m width and 30 cm depth. The effects of dimension, service life, traffic volume, weather and other pavement layers are assumed to be identical for all the wearing courses studied. Fig. 1 shows the system boundary, including the processes of crumb rubber pavement and rubber/coal incineration. It shall be noted that the maintenance is equal to end-of-life for wearing courses because both two processes demolish the used wearing courses and transport them to the recycling plant. Due to lack of reliable data of emissions, the use phase is not considered in the analysis.