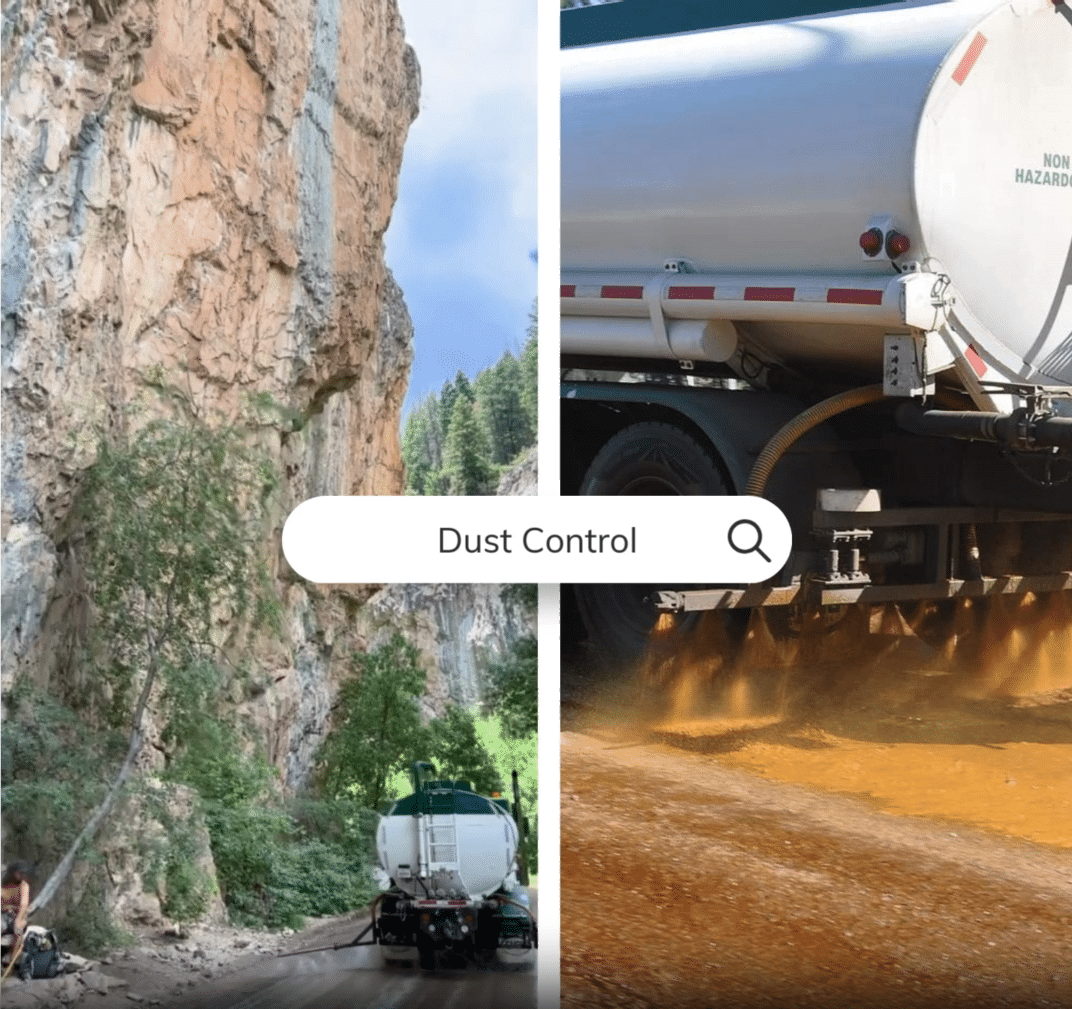

DUST CONTROL

All-Natural, Environmentally Friendly Solution for Gravel Road Stabilization

Dust Control

IntegriBlend 80/20 CS is a blend of liquid magnesium chloride and a Complex Sugar. It’s an all-natural, environmentally friendly solution for gravel road stabilization and dust control. The blends are eco-friendly, but also budget smart. Studies show that entities using our CS blends as part of their gravel road maintenance can cut up to 60% of their gravel replacement and blading costs. The CS’s hygroscopic properties naturally capture moisture from the air keeping the road damp and dust-free for a healthier environment and a safer road.

By enhancing liquid magnesium chloride with complex sugars, we have created a product that is ideal for dust control and stabilization on base courses with fewer plastic materials. The additional binding capabilities and deeper color of the CS blends offer a longer lasting road and an aesthetically pleasing surface. Applications include gravel roads, parking lots, storage areas, agricultural access roads, and horse arenas. IntegriBlend 80/20 CS and IntegriBlend 70/30 CS can be applied by Envirotx, or delivered to your site in 4500 gallon truckload quantities.

- Typical application rates range between .3 – .5 gals/sy

- 70/30 CS is used to increase the binding ability

- Mix the product into the base by a horizontal shaft blending machine or blade mix in a windrow

- Typical rates for stabilization are .2 gal/sy/inch followed by a topical application of .25 gal/sy

- Compact with a rubber tire roller

How does dust control work?

IntegriBlend liquid magnesium chloride is naturally hydroscopic, meaning it attracts moisture from the air keeping the ground moist to control dust. IntegriBlend also has an ionic attraction to plastic materials in the soils binding them together so the product stays on the road and not on the shoulder or ditch.

IntegriBlend M liquid magnesium chloride is a 100% natural product with almost no carbon footprint created using minerals from Utah’s Great Salt Lake. The product is created through a two-year process beginning with ponds flooded with water from the Great Salt Lake. The water is then evaporated using solar power to harvest salt and potash. The magnesium chloride left after the evaporation is then pumped under the lake in an open trench and stored until use.